Leading experts within the field of

Ecochip™ MBBR

Engineering

Technology

Sustainability

Quality

Service

Ecochip™ MBBR

Engineering

Technology

Sustainability

Quality & environment

Service

Wastewater treatment systems are an extremely important part of environmental protection. It is defined as a set of equipment, single treatment technology, linked together to solve the wastewater problems of hospitals, factories, residential areas...

Depending on the nature and characteristics of the wastewater, the equipment and technology components may be different. But the ultimate common goal is to effectively treat the pollutant components.

Solve water pollution, ensure the quality of wastewater before being discharged into the environment according to wastewater standards of the Ministry of Natural Resources and Environment. Save investment and operating costs to the maximum but still meet the durability and usability. Simple upgrade process when needed.

Filtering and separating large-sized wastes, settling sand, separating grease from wastewater... Chemical substances will be added to neutralize pH, flocculation-flocculation, settling tank, flotation….

Taking advantage of the activity of microorganisms in the water such as anaerobic, anaerobic, aerobic... to decompose organic pollutants. Removes dirt, suspended solids remaining in the water. The degree of filtration will depend on the discharge regulations of the Ministry of Natural Resources and Environment on solids content in wastewater.

Current wastewater treatment systems all have a central control panel, depending on the needs of the business that the automation process is high or low.

The concentrated business and service area is a supermarket; shopping mall; market; tourist, sports and entertainment areas; bus station; Railway stations are subject to environmental impact assessment reports.

Craft village industrial cluster is an industrial cluster serving the relocation and expansion of production and business of small and medium-sized enterprises, cooperatives, cooperative groups, household and individual production establishments in craft villages in order to overcome environmental pollution, develop professions and craft villages in the locality.

Not only that, our System Biological Water Treatment is also distributed worldwide

Between 2018 & 2019, pilot testings have been conducted with the Ecochip™MBBR Biochip for nitrification in the coke oven plant Viet Nam Factory Pilot. Engineering support has also been provided by VINA-Eco.

The plant is in operation with the Ecochip™MBBR Biochip with a volume flow rate: Q = 1,440 m³/d.

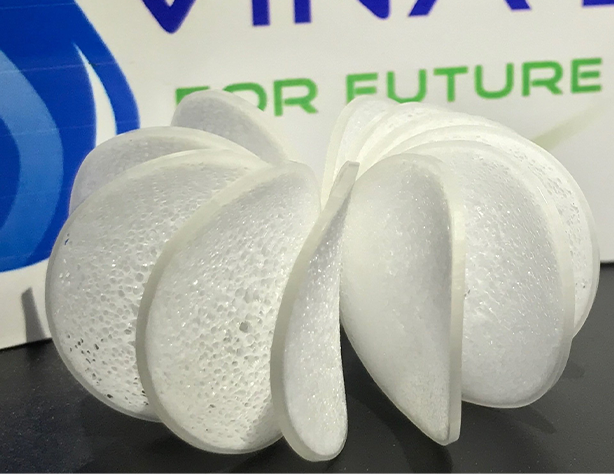

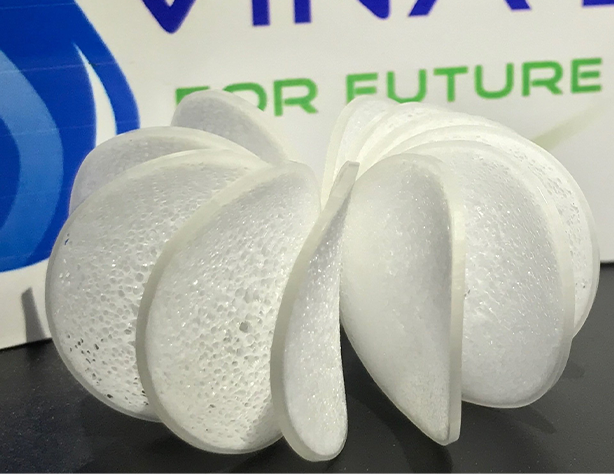

Is a product with the function of nurturing microorganisms to treat wastewater with high concentrations of organic matter

Good handling of COD, BOD, highest nitrate

Is MBBR material with good parameters, minimizing costs for investors.

Small construction land area, Simple small treatment tank, Easy to operate, and durable, no microbial blockage

The laboratory verified surface area is 5,680m2/m3, verified.

One m3 is converted to 165Kg.

My company is Vina eco water environment CO., LTD Headquarters in Vietnam.

Currently, the government has signed trade agreements in many countries. You can easily buy by direct import with low cost.

If you have any other questions, please leave a request and your information we will contact you as soon as online.